In today’s interconnected world where global economies hinge on the efficient transportation of goods across international waters, cargo ships have never been more important. This article takes a closer look at the ‘maritime workhorses’ at the very heart of the global supply chain.

What are the different types of cargo ships?

The term cargo ship covers a number of different vessel types, each with its own shape, size, design and specialist features. In this article, we look at the diverse fleet that underpins the global supply chain; from colossal container ships that can transport millions of standardised containers to smaller Handysize bulk carriers used in ports with size restrictions. Read on to find out more about the six main types of cargo ship (container ships, general cargo ships, tankers, dry bulk carriers, reefer ships and Ro-Ro ships).

What is a container ship?

A container ship is a specialised vessel that is specifically designed to transport standardised cargo containers of various sizes (e.g. 20-foot and 40-foot containers). These containers can be easily loaded, secured and stacked on the ship and unloaded at ports worldwide. Container ships are categorised by their capacity, which is measured in twenty-foot equivalent units (TEUs), with some of the largest ones able to carry over 20,000 TEUs of cargo.

Also known as ‘container vessels’ or ‘box ships’, they are equipped with advanced technology which enables them to transport goods more efficiently and economically than other traditional cargo methods. For example, gantry cranes and other specialised container handling equipment allows for the safe and timely loading and unloading of containers at ports. Furthermore, containerization makes intermodal transportation easier, enabling goods to move from ships to trucks and/or trains without being unloaded and reloaded. As a result, container ships have revolutionised the way goods are transported across continents by sea. From machinery to clothing, they enable the movement of goods on a massive scale and play a pivotal role in the global supply chain.

What is a general cargo ship?

As the name suggests, general cargo ships are used to transport various types of cargo. Also known as ‘general cargo vessels’, they are highly versatile and can easily adapt to changing cargo requirements. This flexibility makes them the go-to option for serving ports and routes where there is demand for smaller cargo shipments and/or where there isn’t the infrastructure for larger specialised vessels.

From small coastal vessels to large ocean-going vessels, general cargo ships come in a range of sizes, depending on the intended trade routes and cargo capacity. What they all have in common is that they’re specifically designed to carry mixed cargo, offering a range of stowage options and cargo holds as well as on-board cargo handling equipment. These features mean they can accommodate a variety of non-specialised goods in smaller quantities (e.g. packaged goods, machinery and equipment) all in a single voyage.

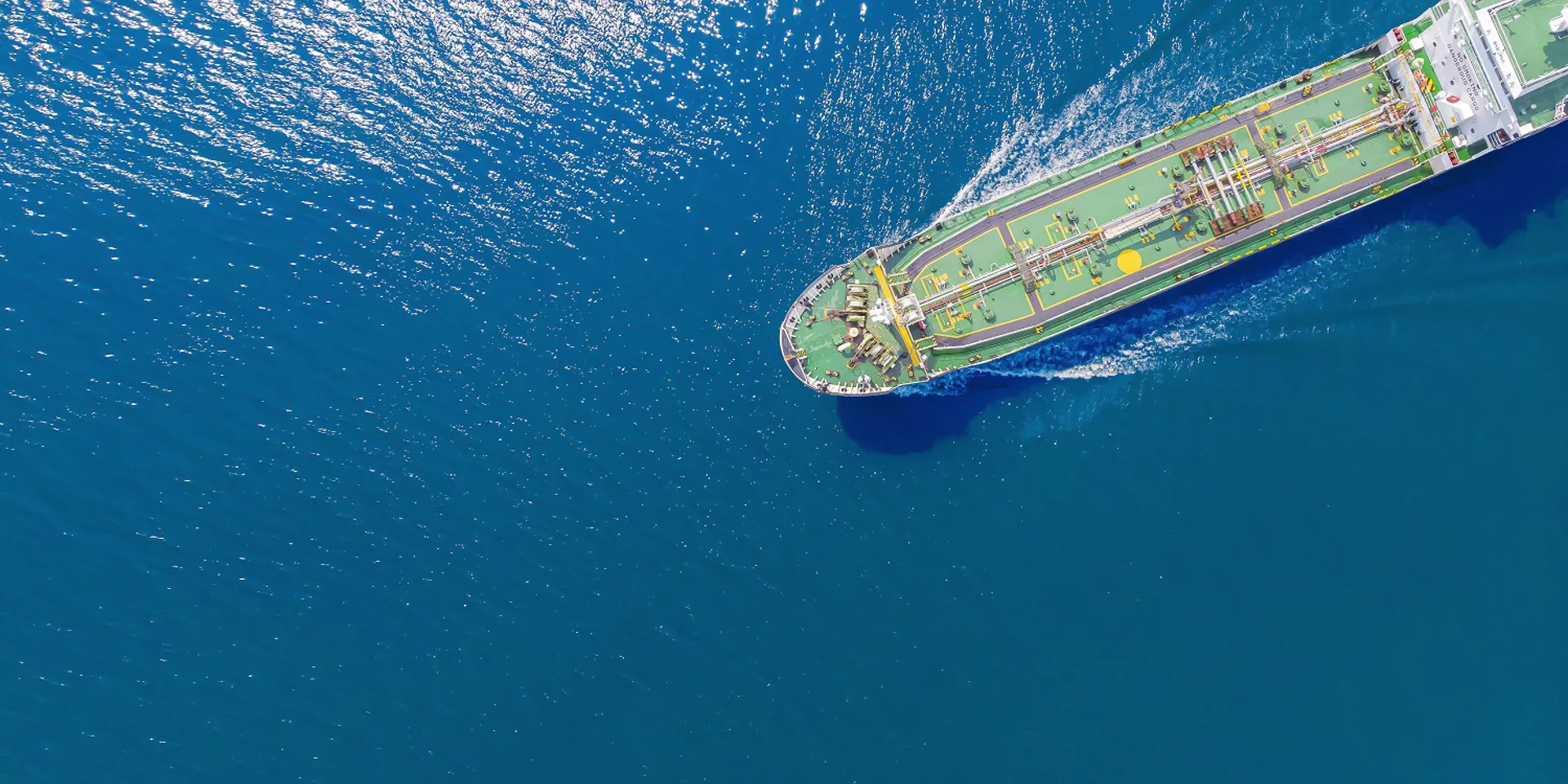

What is a tanker?

A tanker is a ship that is specially designed to safely transport large quantities of liquid cargo over long distances. These vessels have a number of specialised features which allow them to do this. For example, tankers have multiple compartments to carry different liquids simultaneously, and their tanks are constructed from carefully-selected materials to prevent contamination or chemical reactions. Similarly, these vessels are equipped with extensive safety features and advanced pumping systems to load and discharge cargo safely and efficiently.

Tankers vary in size, ranging from smaller coastal vessels to massive ‘supertankers’ which can transport around 2 million barrels of oil or other liquid. Yet what they all have in common is that they are vital to a number of different industries, such as oil & gas, chemicals and liquid gases. Tankers play an important role in delivering a reliable supply of essential products to global markets and can be categorised into a number of types, including oil tankers, chemical tankers, Liquid Natural Gas (LNG) carriers and Liquefied Petroleum Gas (LPG) carriers.

What are dry bulk carriers?

Dry bulk carriers, also known as ‘bulk carriers’, are vessels specifically designed to transport non-liquid and/or non-containerised bulk cargo. They play a key role in transporting the raw materials that power global manufacturing and trade. Dry bulk carriers have a number of features which enable them to safely and efficiently move dry, unpackaged goods (such as grains, minerals, coal and iron ore) across the world’s oceans. For example, dry bulk carriers have open cargo holds without the individual compartments found on container ships and tankers. Similarly, they’re equipped with specialist cargo handling equipment, such as cranes, conveyor systems and grabs.

Dry bulk carriers come in a variety of sizes: Handysize vessels are the smallest bulk carriers, typically used in ports with size restrictions. Panamax vessels are larger, sized specifically to fit the Panama Canal, and are the go-to ship choice for dry bulk cargoes on routes between the Americas and Asia. The largest of all dry bulk carriers, and indeed some of the largest ships on the world’s oceans, are Capesize vessels. Typically they are used for long-haul routes, especially when transporting iron ore and coal. While dry bulk carriers usually have a single deck, for safety reasons some of the larger ones have a double hull design which help to make the vessel more stable.

What is a reefer ship?

A reefer ship, or ‘refrigerated cargo ship’ to give it its full name, is a vessel specially designed to transport cargo requiring temperature control. Most commonly, reefer ships are used to move perishable/frozen goods and products (e.g. fruits, vegetables, meat, dairy products and pharmaceuticals) which need to be kept in a temperature-controlled environment to maintain their quality and/or freshness during transportation. The technology on these ships is so advanced that the adjustable climate control enables the precise humidity to also be set, as well as monitoring systems which sound an alarm if the required conditions change. The ability of these ships to maintain a set temperature for the duration of their transit makes them a key link in the global supply chain of fresh products and medical supplies.

What are Ro-Ro ships?

Roll-on/Roll-off ships, more commonly known as Ro-Ro ships, are vessels specifically designed to transport wheeled cargo that can be rolled on and off the ship without the use of cranes or lifting equipment. Ro-Ro ships are used to move vehicles such as trucks, buses and construction machinery both internationally and domestically, meaning they play a key role in the global logistics and transportation industry. In particular, they are used for passenger ferries and military transport.

Ro-Ro ships are easily distinguishable from other vessels thanks to the following key characteristics: Their open deck configuration means they have open, unobstructed decks which enables cargo to be driven on and off the ship easily. Furthermore, ramps and multiple access points at different levels make moving vehicles on/off even easier. Ro-Ro ships also feature internal vehicle stowage systems (e.g. chocks, lashings, and wheel blocks) to stop movement during transportation, as well as specialist ventilation systems to prevent the build up of exhaust fumes and/or condensation.